- Details

- More images

- Downloads

Products description

With the ECS - Battery Cell Test System you can test your new or used cells / batteries automatically.

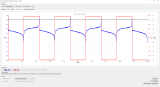

The tests are logged and the results are shown graphically.

You can measure the capacity, the internal resistance and the efficiency of your cells / batteries.

It is also possible to carry out an endurance test with any number of cycles and depth of discharge.

For the test you need two RCM222 and at least one power supply unit to charge the cells / batteries and at least one electronic load for discharge.

The free choice of power supply units and electronic loads allows you to flexibly adapt the maximum charge and discharge current to your needs.

Several power supplies and electronic loads can be controlled in parallel without any problems in order to further increase the current.

Currently available test modules:

- Load with freely adjustable parameters such as Charging current

- Discharging with freely adjustable parameters such as Discharge current and depth of discharge

- Internal resistance measurement

These modules can be called in test configuration files. In this way you can program any test sequences.

Sample test procedures supplied:

charge_standard.bts

- Charge with standard charging current up to the end-of-charge voltage

discharge_standard.bts

- Discharge with standard discharge current up to the final discharge voltage

resistance.bts

- Internal resistance measurement with test current 0.1 C and 0.5 C (adjustable)

charge_discharge_charge_transport.bts

- Charge with standard charging current

- Discharge to final discharge voltage with standard discharge current (including capacity measurement)

- Charging to end-of-charge voltage, measuring the charged Ah and calculating the degree of charge

- Discharging to exactly 50% of the nominal capacity (required for transport and storage)

initialcharge_discharge_charge_transport.bts (complete test of new cells)

- Charge with reduced charging current for brand new cells (initial charge)

- Discharge to final discharge voltage with standard discharge current (including capacity measurement)

- Internal resistance measurement (here at DoD 100%)

- Charging to end-of-charge voltage, measuring the charged Ah and calculating the degree of charging

- Internal resistance measurement (here at DoD 0%)

- Discharging to exactly 50% of the nominal capacity (required for transport and storage)

- Internal resistance measurement (here at DoD 50%)

charge discharge max Current.bts (fast capacity measurement)

- Charge with maximum charge current

- Discharge to final discharge voltage with maximum discharge current (including capacity measurement)

Cell or battery parameters can be configured in Ini files.Statron devices tested by us:

- Laboratory power supply type 3257.3

- Electronic load type 3223

File

This Product was added to our catalogue on 18/08/2020.